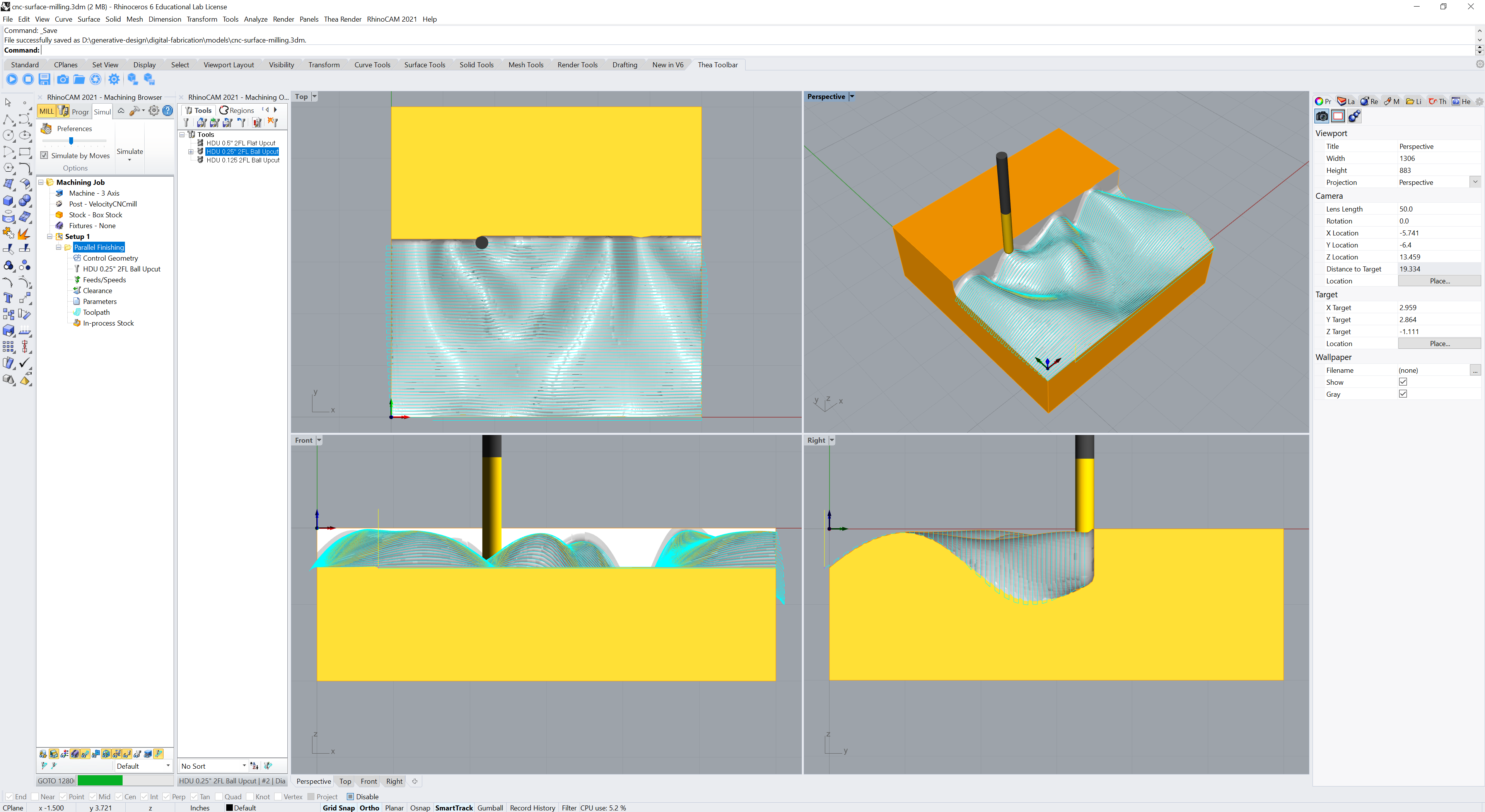

CNC Surface Milling

CNC surface milling with RhinoCAM

Contents

- CNC Surface Milling

- Machine Setup

- Stock

- Tools

- Machining Operations

- Simulation

- Machining

- Thermoforming

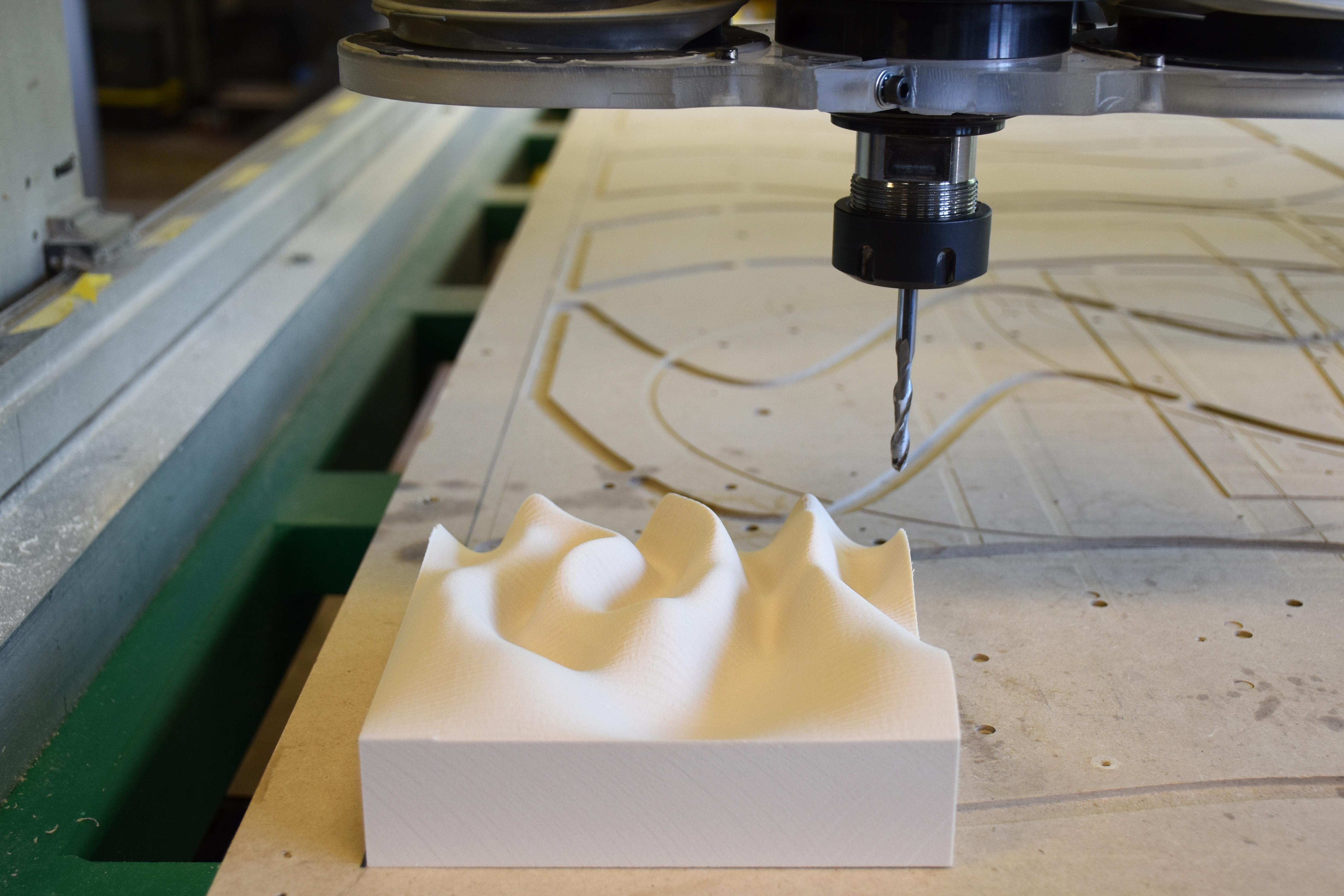

CNC Surface Milling

Use computer numerical controlled (CNC) milling

to digitally fabricate a topographic model

in Rhino with the

RhinoCAM plugin.

Download the Rhino model

for this tutorial.

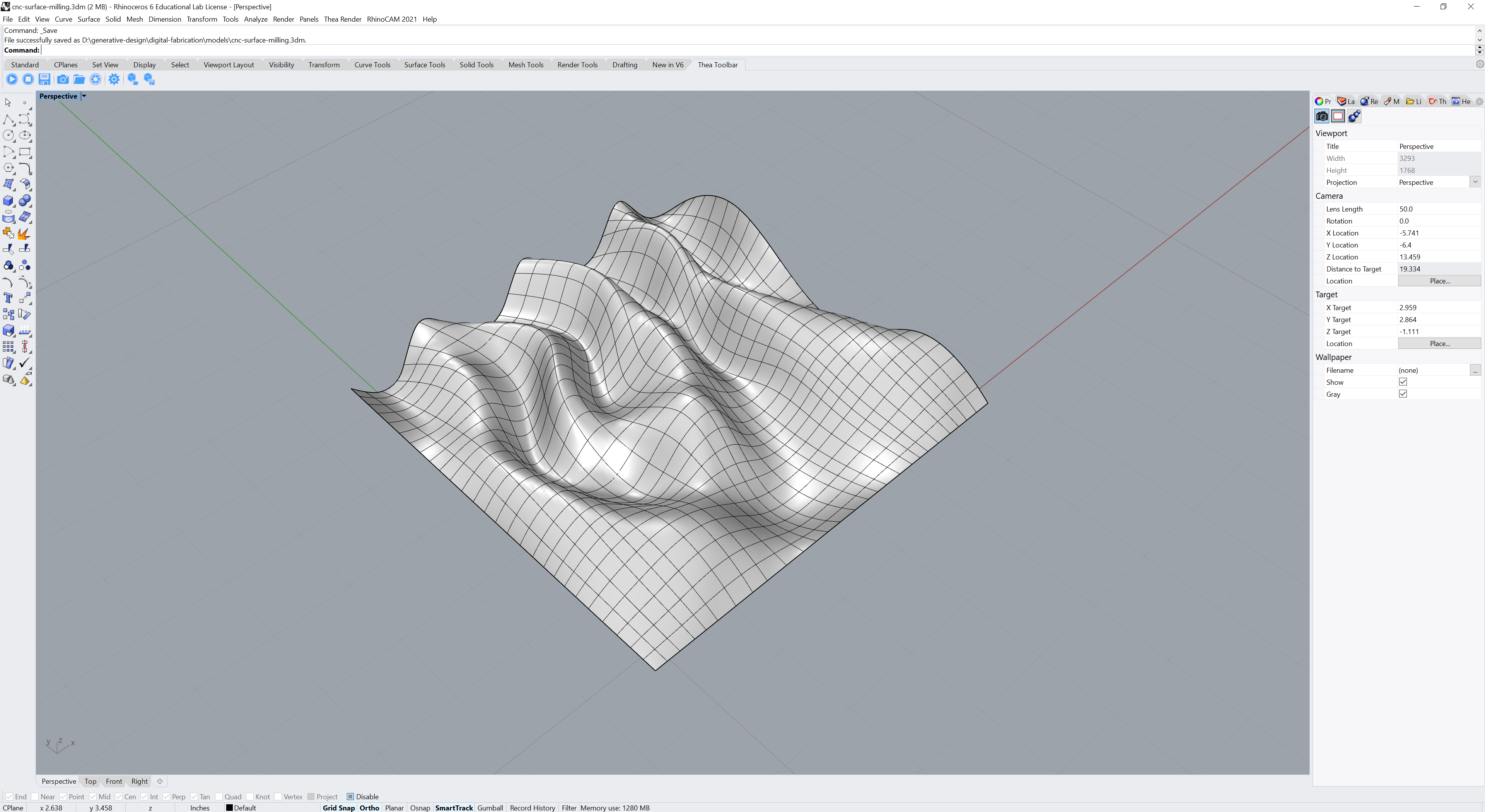

This model was generated by the Grasshopper definition

trigonometric-landforms.gh.

This tutorial is written for a 3-axis

Forest Scientific CNC Router

using VelocityCNCmill as the post processor.

Watch at

or

.

Machine Setup

Start Rhino and set the units to Inches.

In the RhinoCAM menu switch to the MILL module for CNC milling.

In RhinoCAM’s Machining Browser in the Program tab

use the default 3 Axis machine.

In Post set the post processor to VelocityCNCmill.

Set the posted file extension to a .nc numeric control file.

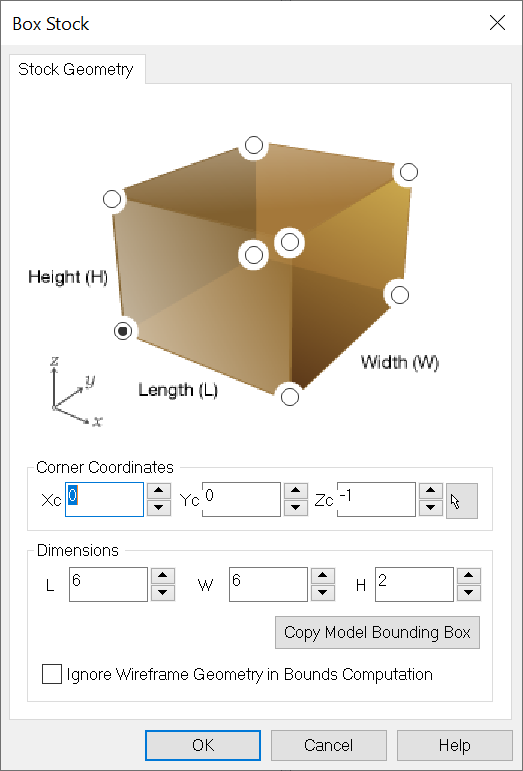

Stock

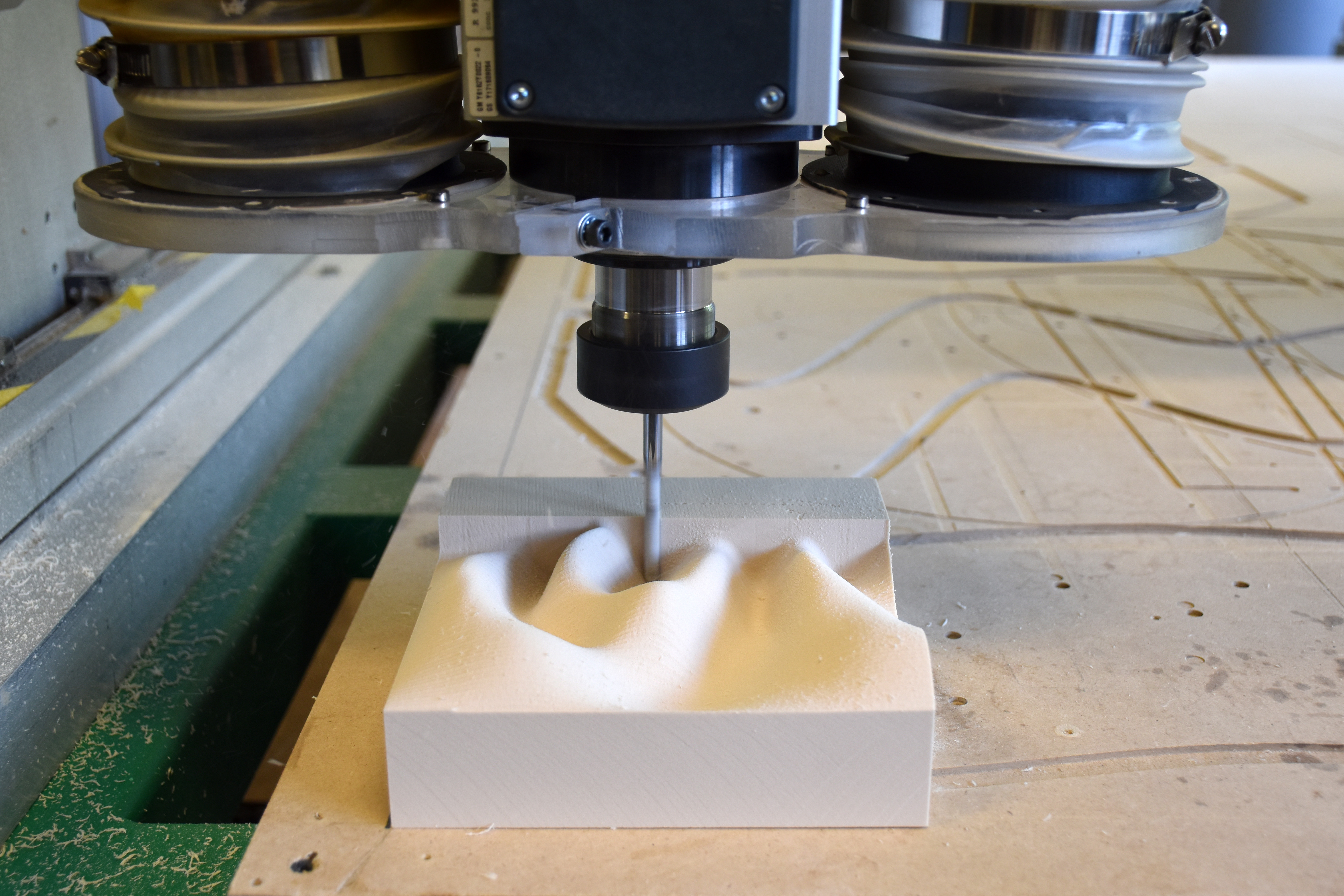

The stock for this CNC milling exercise is a 6” x 6” x 2” block of high-density urethane (HDU) foam board such as Renshape or Signfoam.

In RhinoCAM’s Machining Browser in the Program tab

in Stock select Box Stock

and set the dimensions to 6” long, 6” wide, and 2” high.

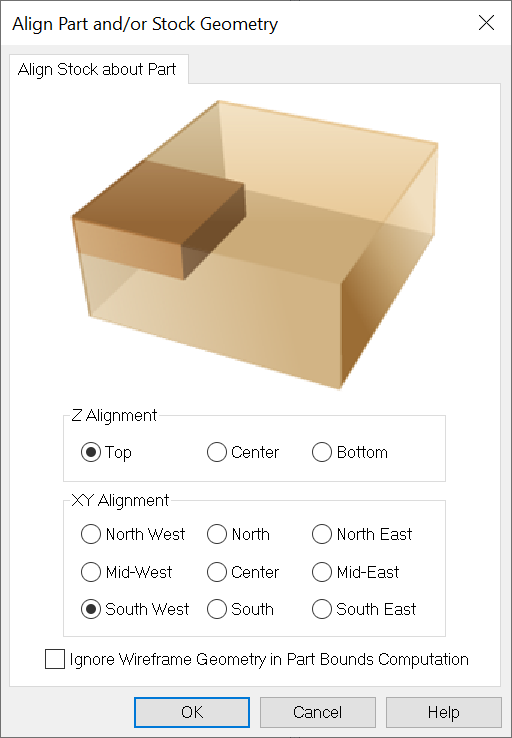

In Align select Align Stock

and set Z alignment to Top

and XY alignment to South West.

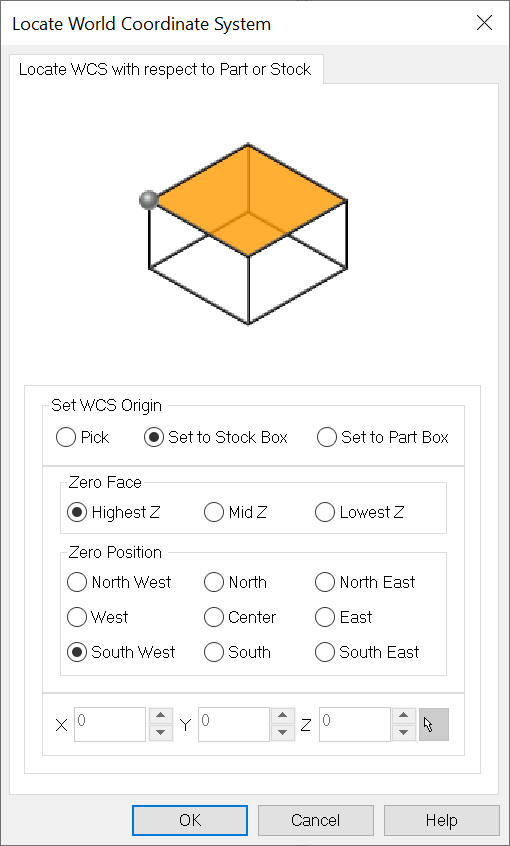

Then in In Align select Set World C.S.

and set the origin to the stock box,

set the zero face to Highest Z,

and the zero position to South West.

Tools

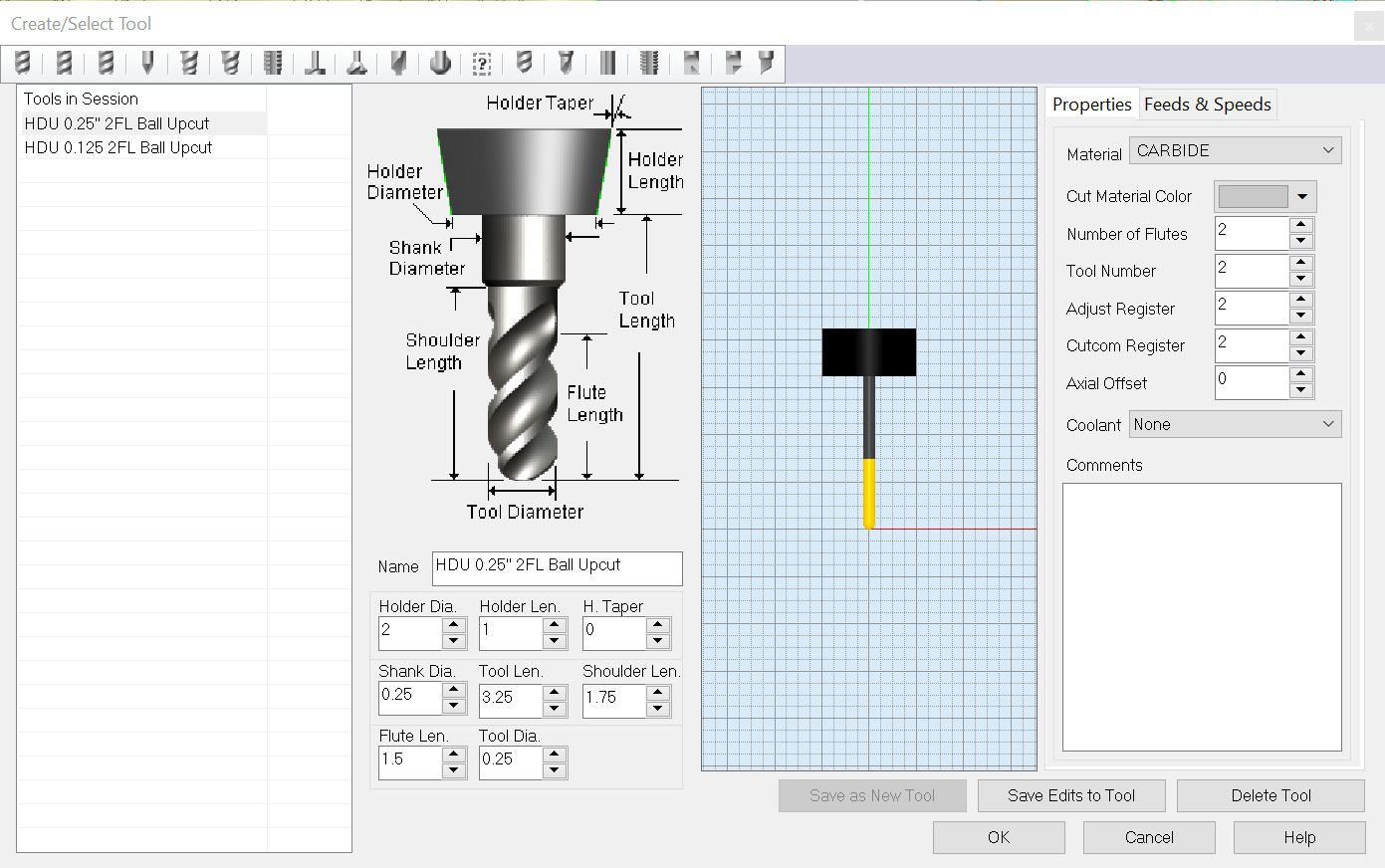

In the Machining Objects panel create a new tool.

This will be a ball end mill made of carbide

with a 0.25” diameter and 2 flutes.

The feed rate and speed depend

on the tool, stock, and machining operation.

Set the tool type to Ball Mill,

tool length to 3.25,

shoulder length to 1.75,

flute length to 1.5,

and the tool diameter to 0.25.

In the properties tab

set the material to carbide

and the number of flutes to 2.

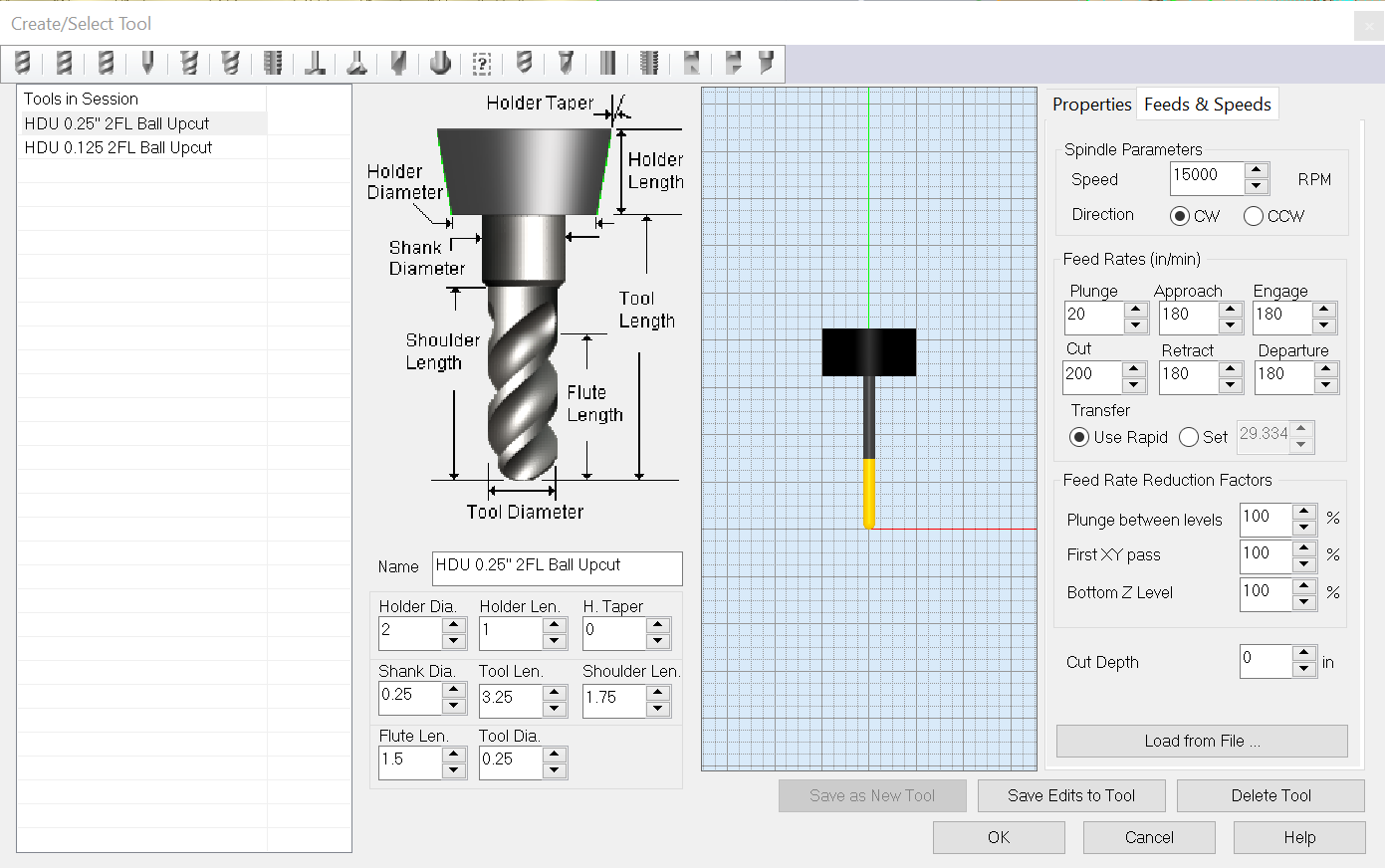

In the feeds and speeds tab

set the speed to 15000 RPM,

plunge to 20,

approach to 180,

engage to 180,

cut to 200,

retract to 180,

and departure to 180.

Save the tool.

Alternatively in the Machining Objects panel load the

cnc_surface_tools.csv

tool library.

Feeds & Speeds

| Speed | Plunge | Approach | Cut | Retract | Departure |

|---|---|---|---|---|---|

| 15000 | 20 | 180 | 200 | 180 | 180 |

Machining Operations

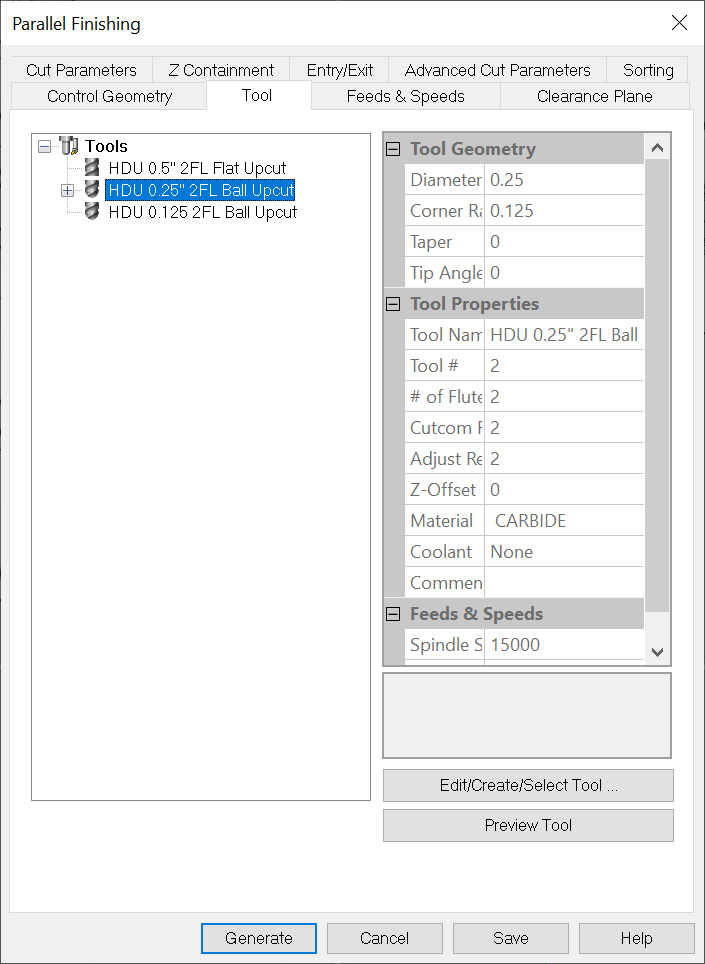

In the Machining Browser in the Program tab

in Machining Operations under

3-Axis Advanced select

Parallel Finishing.

In the tool tab select the 0.25” ball end mill.

In the feeds and speeds tab load the settings from the tool.

In cut parameters set the stepover to 25% of the tool diameter.

Generate the toolpath.

Then right click on the parallel finishing operation

and select post to export the toolpath

as a .nc numerical control file.

Save the numerical control file to a USB drive

to load onto the computer connected to the CNC machine.

Simulation

In the Simulation tab of the Machining Browser

under Simulate select Play

to simulate the machining operation in Rhino’s viewports.

Machining

Checklist

- …

Thermoforming

Checklist

- Turn power switch on (at the back bottom)

- Set mode to

Acrylic 8and start heating - Raise bed, tape down model, and lower bed

- Open cover, place acrylic sheet, and close cover

- Pull heating element forward

- Wait 90 seconds until acrylic is hot

- Push heating element back

- Turn off vacuums

- Raise bed to form the model

- Cool model with air hose

- Puff the acrylic to release the model

- Open cover and remove model